In simple words it is the movement of mass per unit time. If youre working in the metalworking industry even youre engineers you will try to find one online calculator to help you calculate the weight of various metals and steels including ms plate gi sheet structural steel ms angle mild steel steel bar square tube angle aluminum etc.

Pipe Thickness Calculator As Per Asme B31 3 The Piping Engineering World

Pipe Wall Thickness Calculation As Per Asme B31 3 Youtube

Pressure Piping Minimum Wall Equations And Calculator Engineering Reference And Online Tools

How to calculate weight of pipe in kgm ms square tube weight calculator gi pipe weight calculation formula tube weight per foot calculator Searches related to tube weight per foot calculator.

How to calculate thickness of pipe. Whether you are bending pipe for running electrical conduit or a metal project calculating the bend for the start and end point can be an important factor. These numbers are just estimates. The imperial formula is.

This formula can be a useful tool when planning your piping project but keep in mind that it does not account for adjustments in weight. The final factor controlling a pipes viscosity is the fluids viscosity. Engineers calculate the maximum allowable pressure P inside a pipe by using Barlows formula which relates pressure to the nominal wall thickness t the allowable stress S which is the SYMS and to the inverse of pipe diameter D.

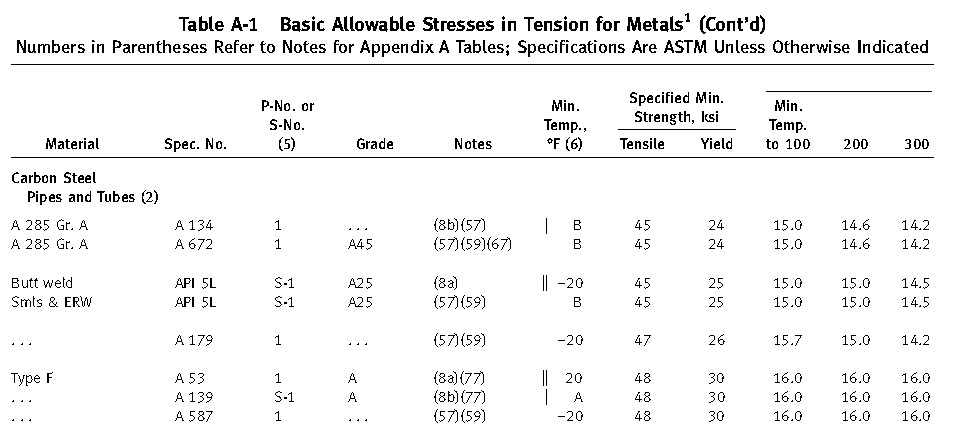

Pipe wall thickness calculation using Barlows formula. Calculate Weight of Pipe - Weight calculating formula for steel pipes Flanges - ASMEANSI B165 Flanges and Bolt Dimensions - Class 150 to 2500 - Diameters and bolt circles for standard ASME B165 flanges - 14 to 24 inches - Class 150 to 2500. Wall thickness inches Wall thickness mm Weight lbft Weight kgm 18 NPS6 041 103 0068 173 024 037 14 NPS8 054 137 0088.

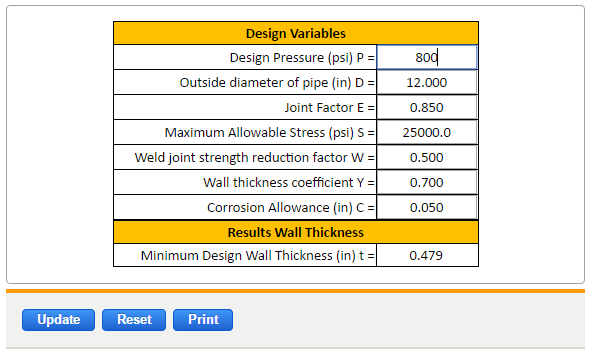

Pipe Weight - Imperial. The wall thickness is 0237 inches and the inside diameter is 4026 in. All equations are programmed inside the utility to help piping professionals to calculate design pipe thickness with ease.

The table above is probably over-estimating pipe size but you can see that a 400 hp vehicle with a dual exhaust system only needs 2 14 2 12 inch pipes. On the other hand as opposed to the thin wall assumption or membrane theory there is the curved plate or thick wall pipe formulas derived from Lames theory whose use is more complicated sometimes with iterations and requires a careful approach like for instance in ASME B 311 code Power Piping ASME B 313 code Process Piping. 25 X 25 Size mm.

WtFt 1069OD Wall ThicknessWall Thickness. A pipe thickness calculator is a tool that calculates the pipe thickness when all required inputs are supplied. In order to calculate heat flow it is first necessary to calculate the thermal resistance R-value for each layer of insulation.

HOOP STRESS Hoop stress σ h for a thin wall pipe can be calculated using the equation below as shown in Figure 3. The software program makes it easy to calculate appropriate insulation thickness for any application. Then below steel weight calculator and metal weight calculator to calculate the weight of metals in.

What is the H oop Stress Formula for Pipe. A thicker fluid flows more slowly under the same pressure. The formula for mass flow rate is given as follows.

It is the circumferential force per unit areas Psi in the pipe wall caused by internal pressure. 20 X 20 Size mm 2 Thickness mm 111 Square Pipe Kg Metre. Square Pipe Size mm Square Pipe Thickness mm Square Pipe Kg Metre.

Wall Thickness and Pipe Schedule. In this equation H is allowable or hoop stress the P is the pressure t is the thickness of. Mass flow rate is the rate of movement of a massive fluid through a unit area.

160 x 80 Size mm 63 Thickness mm 223 Rectangle Pipe Per KgMetre. Through these characters we could calculate the pipe weight how much pressure pipe could bear and the cost per foot or per meter. 5 Thickness mm 18 Rectangle Pipe Per KgMetre.

Calculate pipe weight and price. A pipe is qualified as thick-walled if the pipe radiuspipe thickness ratio is less than 10 or pipe diameterpipe thickness is less than 20 ie Dt 20. Measurment a 90 deg.

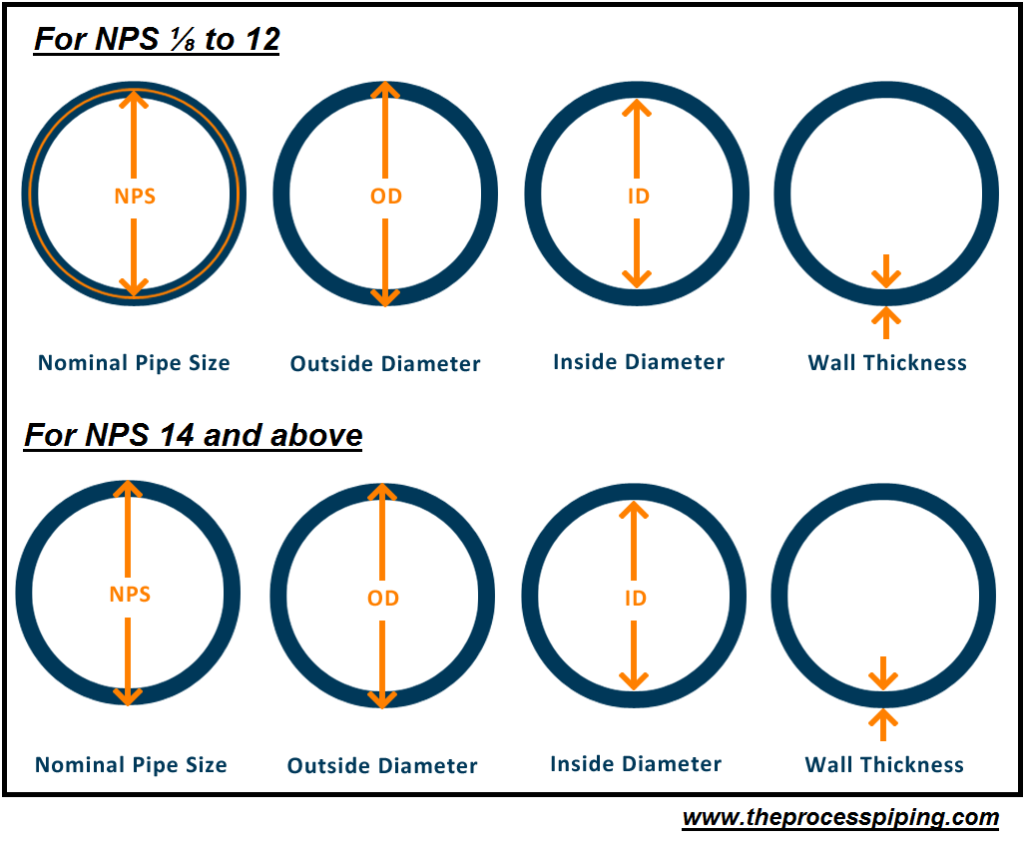

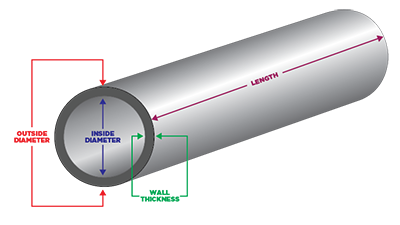

To figure out the pipe weight per foot the wall thickness and diameter of the pipe are required. A wider pipe also produces a higher volumetric flow and a shorter pipe lets a similar pressure drop provide a greater force. A completely description for steel pipe dimension includes outer diameter OD wall thickness WT pipe length Normally 20 ft 6 meter or 40 ft 12 meters.

Pipe nominal size. Calculate pipe weight and price. After youve selected the appropriate die for bending your pipe based on the pipes outside diameter and wall thickness you should be able to find the radius of the bend.

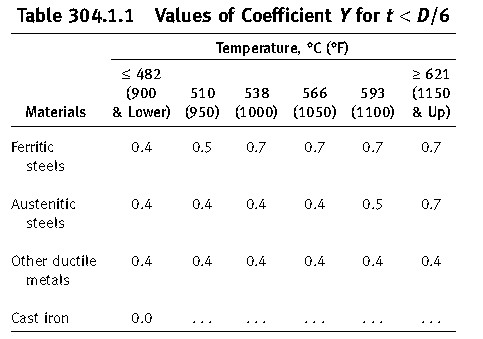

This calculator can be used to calculate the weight of a pipe with - or without - liquid. Pipe Weight Formula This formula can be used to determine the weight per foot for any size of pipe with any wall thickness. This calculator calculates required thickness of a pipe under internal pressure based on criteria specified in section 30211 and 30222 of ASME B313 Pressure Piping.

For pipe insulation the R-value varies not only with the insulation thickness and thermal conductivity k-value but also with the pipe outer diameter and. This pipe thickness calculator calculates required pipe thickness for a process pipe based on ASME B313 Code. Pipe wall thickness calculators can be developed in form of an application VB program or excel sheet program.

The wall thickness of tubing is measured in inches 0035 or by standard gauge from 7 heaviest to 22 lightest which correspond to a range of wall thicknesses. How to Calculate Weight of Pipe. Pipe nominal size.

The standard equation for hoop stress is H PD m 2t. STPG38 Pipe Wall thickness How to Calculate a Pipe Bend. 160 x 80 Size mm.

The outside diameter of 4 Schedule 40 Steel Pipe is 4500 inches. This factor measures the fluids thickness in poise or dyne seconds per square centimeter. Thickness is a critical factor in the success or failure of an insulation system.

Wall thickness inches Wall thickness mm Weight lbft Weight kgm 4 NPS100 45 1143 0438 1113 190 2832 5 NPS125 5563 1413 05. All pipes are assumed to be 16 gauge steel. Then the unit pipe weight kgm 711 x 1683-711 x 002466 2826 kgm.

How to calculate the weight. Specifying pipe insulation is simple with 3E Plus. You can see by the chart at the right not all 12 Gauge allows a thickness between 0101 to 0111.

A simple way to determine the center line radius of a bend of a specific angle is calculate a full circle then divide that number by 360 to find the measurement of one degree. The density of steel is 490 lbft 3 028 lbin 3. Detail information about behind the back calculations is given at the end of this calculator.

The description of API 5L seamless steel line pipe Outer Diameter is 6 58 inch 1683 mm Pipe Wall Thickness is SCH 40 711 mm or 0280 inch length 12 meters. But without the right tool for the job. Viscosity is a measure of the thickness of a fluid and very gloppy fluids such as motor oil or shampoo are called viscous fluids.

Pipe Thickness Calculator As Per Asme B31 3 The Piping Engineering World

Barlow Formula Pipe Thickness Calculation Amarine

Pipe Burst Working Pressure Calculator Barlow S Formula

Nominal Pipe Size And Schedule The Process Piping

Pipe Thickness Calculator As Per Asme B31 3 The Piping Engineering World

Barlow S Formula Wikipedia

Pipe Weight Calculator Imperial And Metric

Simple Ways To Find Wall Thickness Of A Pipe 9 Steps